Collapsible content

Benefits

Directions for use

Guarantees

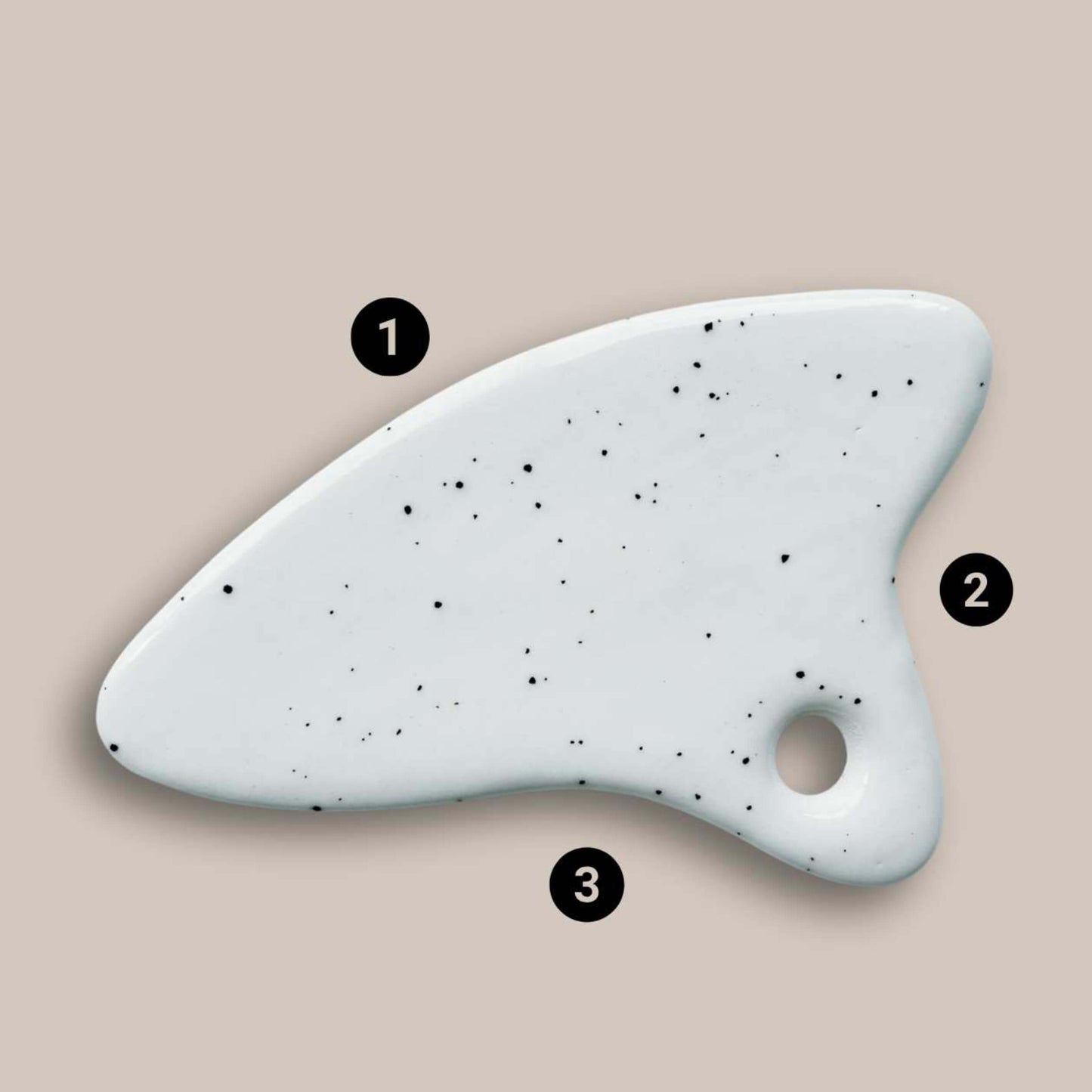

Hollow side

Mandible and chin

Its wide, curved edge adapts perfectly to the chin, sculpting and firming this area while releasing the tensor points.

Curved side

Draw the cheekbones

The rounded side is ideal for massaging the cheeks, stimulating blood circulation and offering a natural toning effect.

Rounded side

Neck and forehead

Its convex edge helps to smooth the skin on the forehead and expression lines, particularly frown lines.

Hand-crafted for perfect application

Clay is a form of ceramic that combines delicacy and functionality, known for its glazed finish that gives it brilliance, colour and impermeability. Creating a piece in clay is a craft process that requires technique, patience and an eye for detail.

Everything begins with white clay, a malleable material that transforms under the artisan’s hands. Before becoming a finished piece, it goes through several stages:

Shaping: The Touch of Hands

The clay is carefully shaped by hand to create the desired piece. Every detail is crafted with precision to form a unique work of art.

Drying: A Long but Essential Process

The freshly shaped piece needs time to dry completely. This stage, though lengthy, is crucial to avoid cracks and fractures that could compromise the piece during firing.

First Firing: The Bisque

At around 1000°C, the clay turns into bisque. It is no longer just dry clay but a porous and durable ceramic, ready to receive the glaze.

Glazing: The Final Touch.

The piece is dipped into a liquid glaze bath or painted with precise brush strokes. Once fired, this glaze will form a glassy layer that protects and enhances the piece, making it waterproof and antibacterial.

Second Firing: The Moment of Truth

Back in the kiln, this time at a temperature between 1000°C and 1100°C, the glaze melts, creating a smooth and glossy surface. The shine intensifies, and the piece reaches its final identity.

The Result: A Unique Piece!

After cooling, the clay piece is ready to be used.